NANOTECHNOLOGY

ABOUT Niimi Sangyo

Niimi Sangyo Co., Ltd. is a material manufacturer that uses plasma melting technology. The high-frequency induced thermal plasma becomes an ultra-high temperature exceeding 10000 ℃. The spheroidization technology for refractory materials (metals and ceramics) using the plasma will be the only one technology in Japan.

Niimi Sangyo Co., Ltd. started plasma melting business in 2019. After the start of the business, Kadotoku Corporation will act as an exclusive agent in Japan and overseas for materials manufactured using plasma melting technology.

PRODUCT & SERVICE

① Zirconia Beads Series

Applications: Nano-dispersion Media (for Bead Mills), Powder Crushing, etc.

Product Ranges

| Model | Particle Size Ranges (μm) |

| φ15 | 10~20 |

| φ20 | 15~25 |

| φ30 | 25~40 |

| φ50 | 40~60 |

Main Properties

| Composition | Yttria Partially Stabilized Zirconia |

| Chemical Formula | 3 %Y2O3-97 %ZrO2 |

| Filling Density (g/cm3) | 3.5 |

| Hardness (HV) | 1315 |

APPLICATION

For Optical Filters

For Pigments for Inks and Paints

For Battery Materials

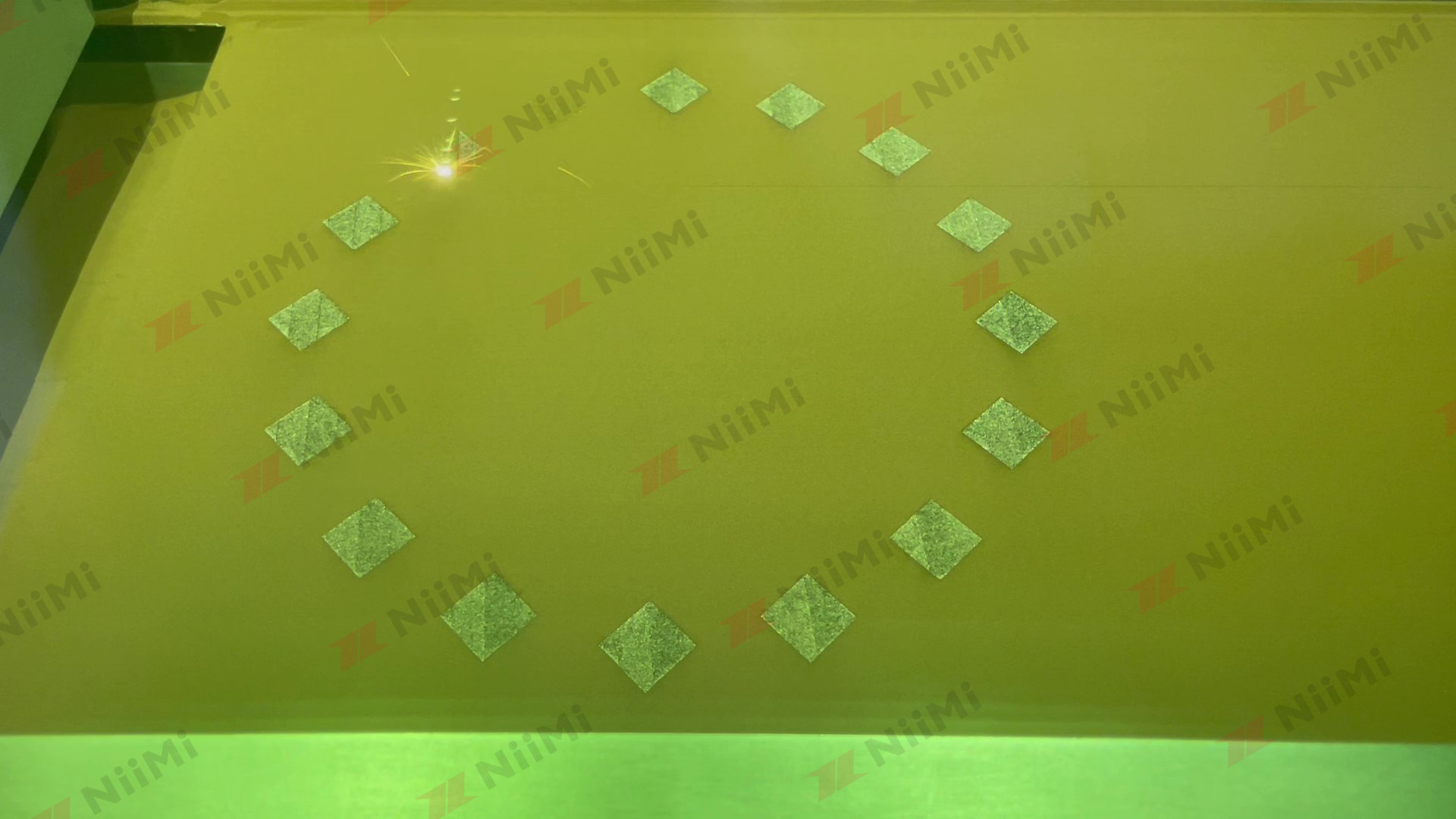

② Modeling Powder Series for Metal 3D Printers (Under development)

P-MMC (Plasma Metal Matrix Composite)

- Light-absorbing material composite Cu powders N-IRCu

- Particle-dispersed composite powders SUS-TiB2

- Cemented Carbide Spheroidized Powders WC-12Co

For Carbide Tools, Metal Processing Elements for Complicated Shapes Applicable for Mold & Die, etc.

③ Contract Manufacturing for Spheroidization

- Melt and spheroidize high-melting-point metals, alloys, ceramics, inorganic substances, etc. at ultra-high temperatures.

- We can realize spheroidization suitable for the customer’s needs.

- We meet requests from customers for customization in manufacturing of spheroidization.

This video is a description of manufacturing for Spheroidization.

Japan`s ONLY ONE Plasma melting technology