Optimize Polyurethane Dispersion performance properties

ABOUT Perstorp

The Perstorp Group is a world leader in several segments of the specialty chemicals market for a wide range of industries and applications.

Since 1997, we have expanded sales of Perstorp products as resin raw materials for adhesive, sealant, paint and ink applications. We offer aqueous conversion agents for waterborne urethane resins (polyurethane dispersions), which are in increasing demand due to environmental concerns.

PRODUCT

Optimize Polyurethane Dispersions performance properties

Selection of Performance Characteristics

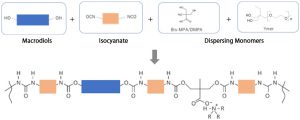

Perstorp offers a choice of PUD components such as Ymer™ and Bis-MPA™ in addition to poly alcohols to achieve the properties (hard to soft, rigid to flexible) required by resin manufacturers.

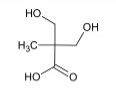

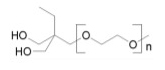

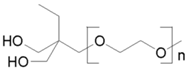

| Product name | Grade | CAS No. | METI No. | Chemical name | Structural formula |

| Bis-MPA | 4767-03-7 | 2-1328 | Dimethylolpropionic acid |  | |

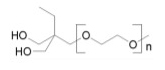

| Ymer™ | N90 | 131483-27-7 | 7-758 | α-[2, 2-bis(hydroxymethyl)butyl] ]-ω-methoxypoly(oxyethylene) |  |

| N120 | |||||

| N180 | |||||

・Low environmental impact technology: low/no VOC content and water dispersibility

・Stable & precise performance characteristics

・Versatile, high-performance coating systems

・Freedom and flexibility to choose precise performance characteristics to differentiate PUD resin formulations

・Enables customization of durability, hardness and flexibility, etc.

Macrodiols Isocyanate Dispersing Monomers

Bis-MPA™

Key raw materials for anionic PUDs

Dimethylolpropionic acid – a diol with a strong neopentyl structure

and low reactivity sterically hindered carboxyl groups

- Easy to formulate stable dispersions

- Low additions to formulations

- Low toxicity

- Fine particle size and good solubility

Ymer™

Nonionic dispersion monomer for solvent-free/low solvent PUDs

- Solvent-free PUD possible

- PH-independent stability

- Improved freeze/thaw stability

- Improved flexibility and chemical resistance

- Low melting point liquid form for easy handling -Increased plant throughput

- Ymer™ alone or in combination with Bis-MPA

Ymer™ expands the range of formulations

Ymer grades (long and short ethoxy chains) help you optimize your formulations

The main parameters affected by the different chain lengths are

- Dispersibility – improved with shorter chains

- Stability – improved with longer chains

- Hardness – improved with short chains, reduced with long chains

- Softness/flexibility – improved with longer chains

| Ethoxy Chains | ||||

| length |  | |||

| YmerTM N120 | ||||

| short | ||||

SPECIFICATION

| Product name | Appearance (At RT) | Mw (g/mol) | OH value (mg KOH/g) | Acid value (mg KOH/g) | Water (%) | m.p.(℃) | Ash(ppm) |

| Bis-MPA | White wax | 134 | 810-860 | 405-425 | Max0.3 | 180 | Max100 |

| Product name | Appearance (At RT) | Mw (g/mol) | OH value (mg KOH/g) | Water (%) | m.p. (℃) | Viscosity (mPa・s/50℃) |

| Ymer™N90 | White wax | 1200 | 84-93 | Max0.5 | 25-45 | 66 |

| Ymer™N120 | White wax | 1000 | 100-120 | Max0.5 | 20-40 | 60 |

| Ymer™N180 | Clear liquid | 600 | 166-191 | Max0.5 | 5-15 | 52/189(25℃) |

APPLICATION

- Wooden flooring: hard and durable coating

- Leather and textiles: high flexibility and abrasion resistance

- Wood, metal and plastic coatings: weather resistance and anti-yellowing

- Automotive dashboards and other plastics: Soft-feel tactile coating

- Adhesives for shoes, wood products, furniture, automotive interiors, etc.